Page 20 - POLYMER TECHNOLOGY

P. 20

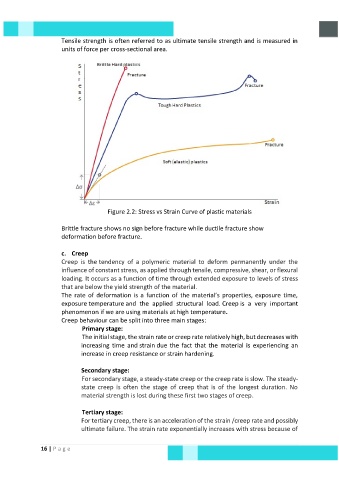

Tensile strength is often referred to as ultimate tensile strength and is measured in

units of force per cross-sectional area.

Figure 2.2: Stress vs Strain Curve of plastic materials

Brittle fracture shows no sign before fracture while ductile fracture show

deformation before fracture.

c. Creep

Creep is the tendency of a polymeric material to deform permanently under the

influence of constant stress, as applied through tensile, compressive, shear, or flexural

loading. It occurs as a function of time through extended exposure to levels of stress

that are below the yield strength of the material.

The rate of deformation is a function of the material’s properties, exposure time,

exposure temperature and the applied structural load. Creep is a very important

phenomenon if we are using materials at high temperature.

Creep behaviour can be split into three main stages:

Primary stage:

The initial stage, the strain rate or creep rate relatively high, but decreases with

increasing time and strain due the fact that the material is experiencing an

increase in creep resistance or strain hardening.

Secondary stage:

For secondary stage, a steady-state creep or the creep rate is slow. The steady-

state creep is often the stage of creep that is of the longest duration. No

material strength is lost during these first two stages of creep.

Tertiary stage:

For tertiary creep, there is an acceleration of the strain /creep rate and possibly

ultimate failure. The strain rate exponentially increases with stress because of

16 | P a g e