Page 23 - POLYMER TECHNOLOGY

P. 23

The differences between these tests include the specimen size, notch face direction,

type of hammer, and type of tested material. The Charpy test examines specimens

with the notch facing away from a striking ball peen hammer. The Izod test, on the

other hand.

2.2 Electrical Properties of Plastic

Electrical properties of polymers are very important to a wide range of industries such

as automotive, aerospace, building products, marine, packaging and consumer goods.

Various factors such as dielectric strength and dielectric constant are important to

determine the nature of the polymer material, specifically regarding its efficiency and

conductivity.

Generally, plastic material used as an insulator in electrical applications. Therefore,

dielectric strength and dielectric constant are important properties of the plastic

materials.

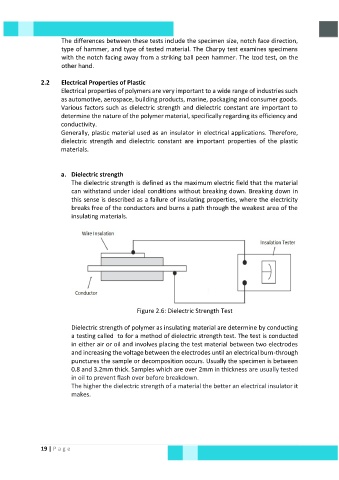

a. Dielectric strength

The dielectric strength is defined as the maximum electric field that the material

can withstand under ideal conditions without breaking down. Breaking down in

this sense is described as a failure of insulating properties, where the electricity

breaks free of the conductors and burns a path through the weakest area of the

insulating materials.

Figure 2.6: Dielectric Strength Test

Dielectric strength of polymer as insulating material are determine by conducting

a testing called to for a method of dielectric strength test. The test is conducted

in either air or oil and involves placing the test material between two electrodes

and increasing the voltage between the electrodes until an electrical burn-through

punctures the sample or decomposition occurs. Usually the specimen is between

0.8 and 3.2mm thick. Samples which are over 2mm in thickness are usually tested

in oil to prevent flash over before breakdown.

The higher the dielectric strength of a material the better an electrical insulator it

makes.

19 | P a g e