Page 18 - SCREEN PRINTING FOR BEGINNERS

P. 18

Mesh information for the Screen Printer

There are many types of mesh There are two directions to the

fabrics available and they can be threads or yarns in mesh due to

made from many types of the mode of manufacture. The

substrates. There are multifilament length (or feed from the machine)

and monofilament threads, is called WARP. The thread

stainless steel, nylon, polyester, and direction that spans the width of

silk. (where the name silk screen the roll is called WEFT.

came from) This note is limited to Mesh fabric is flexible and will

monofilament polyester, the best return to the unflexed position.

choice for screen printing This fabric property is called elastic

garments. You have for example memory.

many choices in thread weave Mesh fabric has a flex limit referred

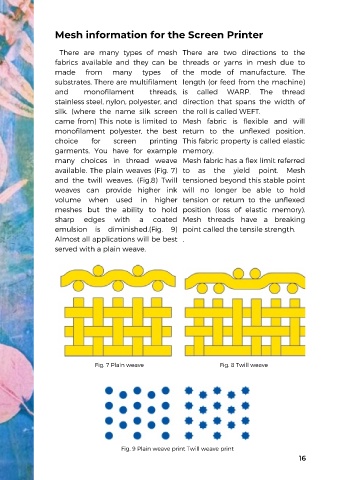

available. The plain weaves (Fig. 7) to as the yield point. Mesh

and the twill weaves. (Fig.8) Twill tensioned beyond this stable point

weaves can provide higher ink will no longer be able to hold

volume when used in higher tension or return to the unflexed

meshes but the ability to hold position (loss of elastic memory).

sharp edges with a coated Mesh threads have a breaking

emulsion is diminished.(Fig. 9) point called the tensile strength.

Almost all applications will be best .

served with a plain weave.

Fig. 7 Plain weave Fig. 8 Twill weave

Fig. 9 Plain weave print Twill weave print

16